In the high-stakes environment of an operating room, success depends on preparation and the quality of the instruments at hand. While scalpels and sutures often get the spotlight, the humble clamp plays a vital role in patient outcomes. These locking forceps are the unsung heroes of surgery, designed to hold tissue, occlude blood vessels, or secure other materials during procedures.

Choosing the right clamp medical tool can significantly impact surgical efficiency. Surgeons rely on these instruments to maintain a clear field of view and prevent excessive blood loss. Whether it is a hemostat for controlling bleeding or a towel clamp for securing drapes, the precision of the grip is everything. A slip or a failure to lock securely can lead to complications, which is why sourcing high-quality instruments is non-negotiable for medical facilities.

The Anatomy of a High-Quality Surgical Clamp

Not all surgical instruments are created equal. A superior clamp medical tool is defined by its material, design, and durability. Most high-grade clamps are forged from surgical stainless steel, which offers resistance to corrosion and the ability to withstand repeated sterilization cycles.

The locking mechanism, often a ratchet system, is crucial. It allows the surgeon to apply varying degrees of pressure without needing to maintain manual force constantly. This frees up the surgeon's hands for other critical tasks. The jaws of the clamp also vary widely—some are serrated for a firm grip on tissue, while others are smooth to prevent damage to delicate structures like blood vessels. Understanding these subtle differences ensures that the surgical team selects the correct instrument for the specific procedure at hand.

GreyMedical®: Elevating Surgical Standards

When discussing quality instrumentation, the manufacturer behind the tool is just as important as the tool itself. GreyMedical® is a privately owned medical technology company dedicated to innovation and excellence in the craft of surgical instruments. Their commitment to precision engineering ensures that every clamp medical tool they produce meets rigorous standards.

GreyMedical® understands that surgeons need reliability. Their manufacturing process focuses on creating instruments that feel balanced in the hand and function flawlessly under pressure. By prioritizing innovation, they help medical professionals perform at their best, knowing their tools will not fail them when it matters most.

Selecting the Right Instrument for the Job

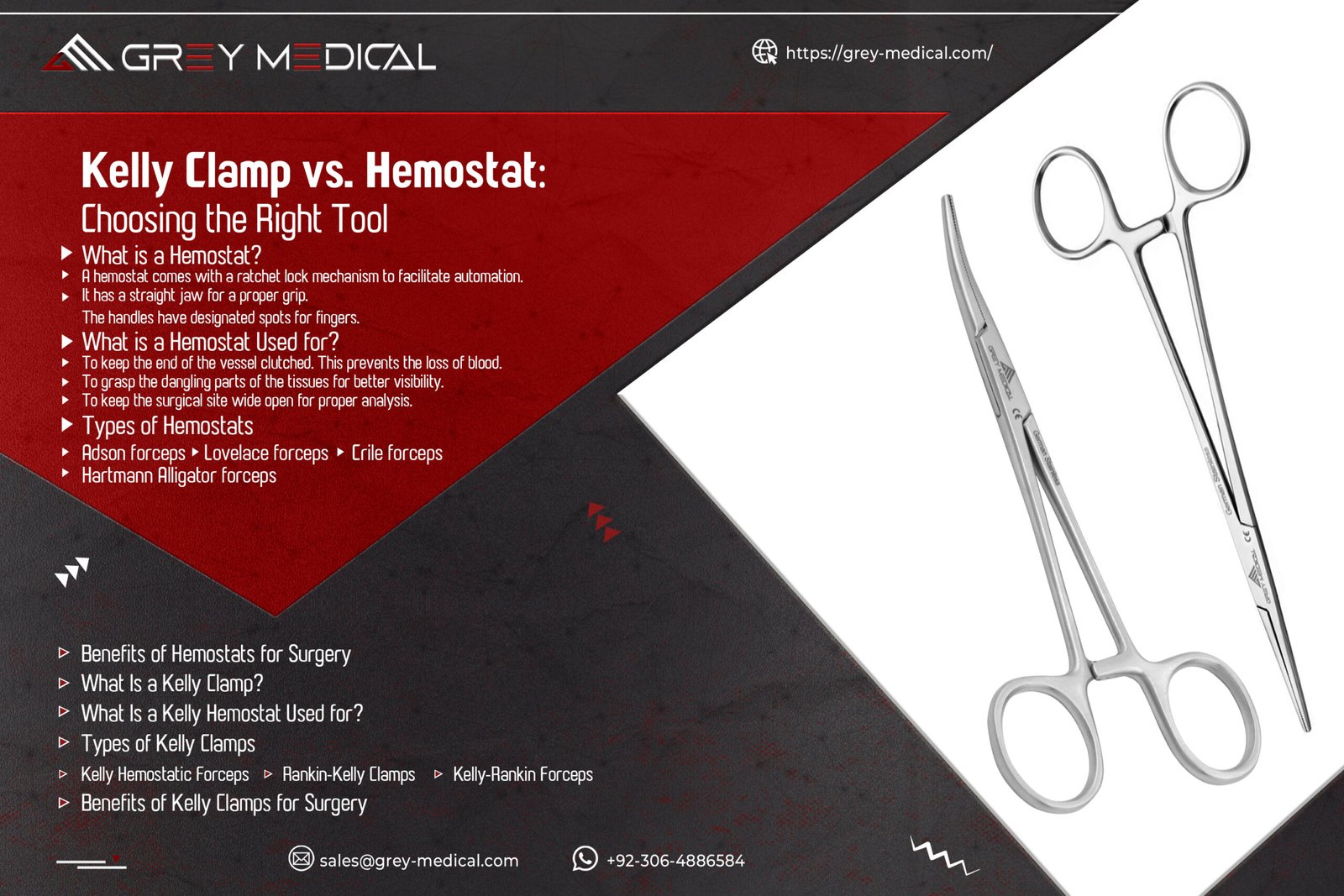

The variety of clamps available can be overwhelming. From the delicate Mosquito clamp used in pediatric or plastic surgery to the robust Kelly clamp used in general surgery, each has a specific purpose. Using a generic or incorrect clamp medical tool can cause tissue trauma or ineffective hemostasis.

Facilities must invest in a diverse inventory to cover various surgical specialties. Regular maintenance and inspection protocols are also essential. Even the best steel can degrade over time, and a clamp with a misaligned jaw or a loose ratchet is a liability. Partnering with trusted suppliers like GreyMedical® ensures that hospitals have access to durable equipment that stands the test of time.

Conclusion

Surgical success is a combination of skilled hands and reliable tools. The right clamp medical tool provides the control and safety necessary for modern medical procedures. By understanding the importance of material quality, specific design features, and trusted manufacturers like GreyMedical®, healthcare providers can ensure they are equipped to deliver the best possible patient care. Investing in excellence is not just about buying a tool; it is about investing in patient safety.