In the current rapidly evolving industrial atmosphere, manufacturers are under immense pressure to perform in terms of efficiency, quality, and reliability. Ranging from heavy machineries to precision parts, the functional efficacy of various industrial processes relies highly upon designs of manufacturing equipment design. A well-designed equipment provides effortless functionality, eliminates wastages, and generates quality results.

The Middle East companies, especially in the UAE, are looking towards the Manufacturing solutions UAE as a means of benefiting from the latest technology innovations in manufacturing. This is achieved through utilizing superior equipment design in combination with professional manufacturing services.

What is Manufacturing Equipment Design?

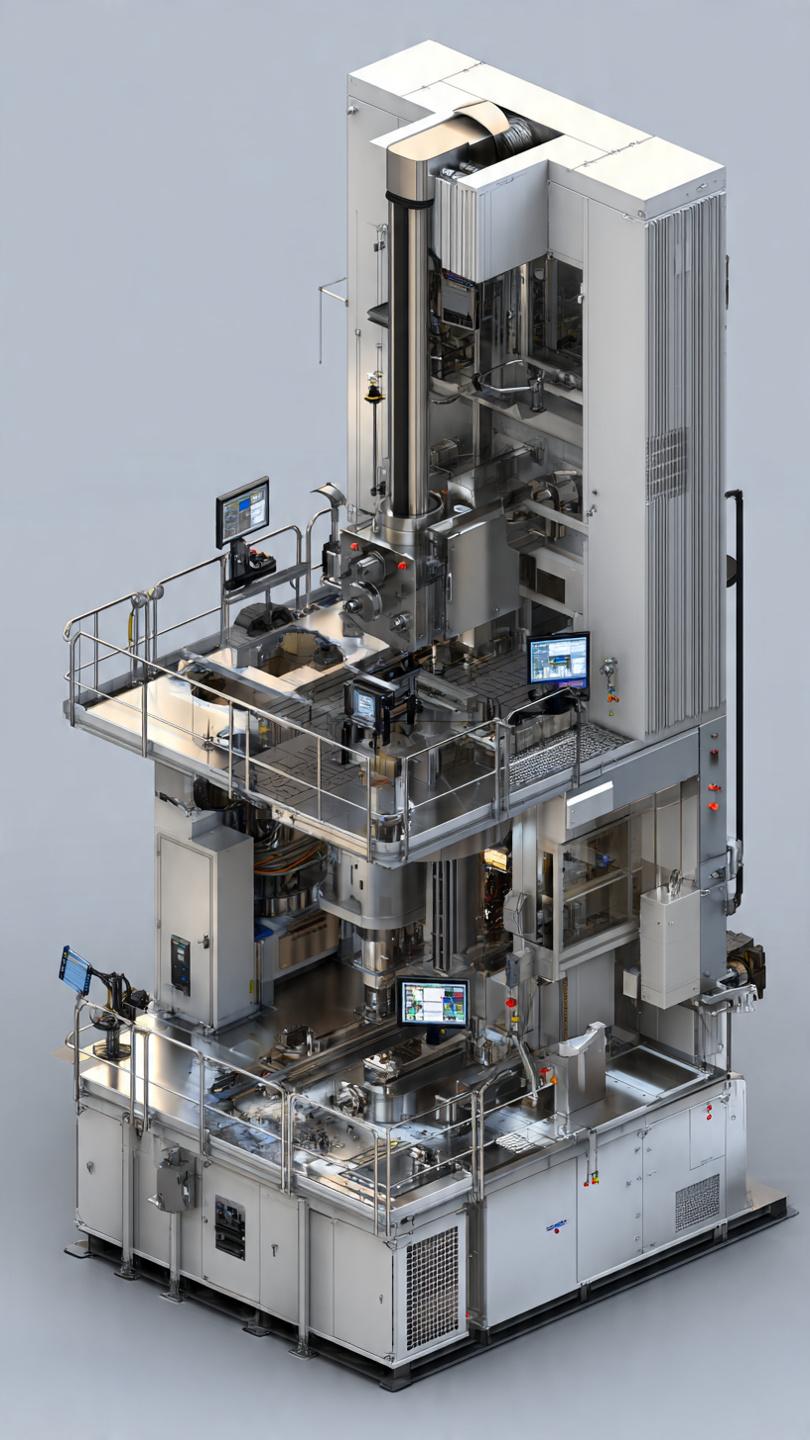

Design in manufacturing equipment encompasses developing and optimizing equipment and tools that are applied in production. The process seeks to ensure that production equipment designed is efficient and has met certain standards.

Key points include

-

Ergonomic and functional design for ease of use

-

Materials for durability and long life

-

High-precision engineering to ensure quality output

-

Integration with Existing Production Systems

-

Integration with existing systems

Spending on equipment design can eliminate equipment downtime, improve safety, and promote quality.

Role of Design of Manufacturing Equipment in Contemporary Industry

An optimal manufacturing system helps in gaining several benefits:

Precision and Accuracy

Appropriate equipment design will facilitate the manufacturing of the parts to precise dimensions.

Operational Efficiency

Improved work flows and designs increase efficiency and reduce downtime.

Cost Reduction

It ensures energy efficiency, material preservation, and low maintenance.

Adaptability

The machines can be upgradetable/downgradable according to changing production needs associated with scalability.

Safety and Compliance

Properly made equipment would be set according to safety standards.

How Manufacturing Solutions UAE Assist in Equipment Design

The UAE has also proved to be a major destination for industrial manufacturing and engineering services. Businesses providing Manufacturing solutions UAE have skilled professionals, modern manufacturing facilities, and quality control processes to achieve successful outcomes.

Advantages of opting for the manufacturing solutions of the UAE include:

-

Access to certified and experienced engineers

-

The lab is equipped with advanced facilities and machinery to

-

Compliance with international quality and safety standards

-

Timely delivery and scalable production capabilities

These technologies enable businesses to use the latest technology in equipment design and still strive for excellence in their operations.

Industries Where Manufacturing Equipment Design Can Be Applied.

Designation of equipment in manufacturing is very important in different fields such as:

Oil & Gas

The equipment should resist high pressure, temperature, and corrosive materials. The equipment design should be accurate.

Vehicles

Customized machines manufacture components with strict tolerances for performance.

Aerospace

Highly precise equipment is required because safety-critical components have to adhere to strict industry standards.

Industrial Machinery

The optimized designs are also involved in a consistent manufacturing process. There are less operational errors involved

Construction

Effective machine design ensures that structural parts can be built quickly and precisely.

In these sectors, professional Manufacturing solutions UAE will provide integrated solutions for a seamless process and desired outputs.

Customer Satisfaction in Manufacturing Equipment Design

Customer satisfaction is another key area in industrial manufacturing. Firms offering design services for manufacturing equipment concentrate on the following:

-

Quality Assurance: Where all parts and machines obey strict norms

-

Timely Delivery: On-time project completion to prevent operational setbacks

-

Technical Support Services: Offering assistance and maintenance for optimal functionality

They experience reduced downtime, increased productivity, and access to a reliable partner to undertake future projects.

Disadvantages of Professional Equipment Design Services

Increased Productivity

Well-designed equipment layout improves efficiency in business workflows.

Lower Operating Expenses

Efficient machines use less energy. There is also less material usage.

Long-Term Rel

The use of quality materials and precision engineering ensures longer equipment lifespan.

Flexibility and Scalability

The equipment can then be modified for different products, volumes, or processes.

Compliance & Safety

The designed professional complies with global standards for safety and industry.

By combining all these benefits, it is now possible for companies to enjoy greater profits and project success.

Quality Assurance and Continuous Improvement

Continual improvement is one of the principles in the industrial era of manufacturing. The firms involved in the provision of Manufacturing solutions UAE exercise quality control measures, which include:

-

Dimensional verification, functional verification

-

Material Testing and Certification

-

Process monitoring to ensure steady output

These methodologies ensure the effective functioning of the equipment used in the manufacturing process, thereby increasing overall productivity and customer satisfaction.

Future of Manufacturing Equipment Design

Technological advancements in digital technologies, automation, and IoT integration are influencing the future course of designing manufacturing equipment. In smart machines, predictive maintenance, real-time monitoring, and increased accuracy are possible.

Key trends are:

-

Automation and robotics integration to enable rapid production

-

Digital Twin Simulation Process Optimization

-

Sustainable designs that use little energy and material

-

More customization and adaptability for client-specific demands

Embracing these trends, companies can provide the best Manufacturing solutions UAE to meet the requirements of today and tomorrow.

Conclusion

In the modern industrial landscape, efficiency, precision, and reliability are non-negotiable. Manufacturing equipment design plays a pivotal role in ensuring operational excellence, supporting productivity, and minimizing costs. Partnering with providers offering professional Manufacturing solutions UAE enables businesses to leverage advanced technologies, tailored designs, and high-quality production standards.

Through a focus on innovation, quality, and customer satisfaction, manufacturing companies can achieve long-term success, strengthen client relationships, and maintain a competitive edge in diverse industrial sectors.

FAQs

1. What is manufacturing equipment design?

It is the process of creating and optimizing machinery, tools, and systems used in production to ensure efficiency, precision, and safety.

2. Why is manufacturing equipment design important?

Proper design improves product quality, reduces errors, enhances efficiency, and ensures compliance with industry standards.

3. What are Manufacturing solutions UAE?

They are professional services in the UAE that provide advanced manufacturing capabilities, expert engineering, and quality-controlled production.

4. Which industries benefit most from equipment design services?

Industries such as oil and gas, aerospace, automotive, industrial machinery, and construction gain significant advantages.

5. How does customer satisfaction factor into equipment design?

Delivering tailored, high-quality, and reliable solutions ensures operational efficiency, timely delivery, and long-term client trust.