HDPE Sheet & Its Core Composition Explained

High Density Polyethylene (HDPE) is a very commonly recycled type of plastic and is well accepted in most recycling centers. Being made from petroleum based polymers, the HDPE sheets are known for their strength and accumulation resistance. These sheets are non-toxic, very light-weight highly moisture resistant and extremely easy to cleanIdeal as a project substrate when working with mediums that do not require long-term stability like air-dry clay. Used for everything from industrial flooring to waste containers, HDPE sheet is perfect for any application that requires strength, durability and low maintenance. Due to their smooth surface finish, excellent thickness tolerances and low base material removal, they are ideal for easy processing, cutting, welding and tight bending. With rising demands for high quality products, cost-effective and durable HDPE sheet is becoming the world’s product of choice criminal law firms in Texas.

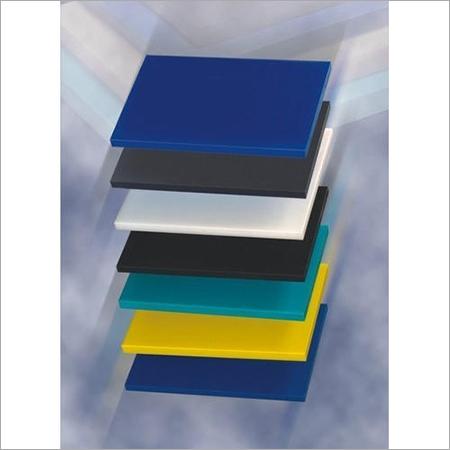

HDPE Sheets That Make the Most Popular Can Be Found in Different Types - Most Favorite Qualities of HDPE Sheets

One of the key benefits of HDPE sheets is their utility in extremely corrosive environments as they are highly resistant to many acids, alkalis and other chemical compounds. High tensile strength, good flexibility, and crack resistance under stress are other properties. For example 2mm and 3mm HDPE sheets provide a good combination of flexibility and toughness and are ideal for liners, partitions or protective shells. HDPE sheets can be UV-stabilized to function well in continuous sunlight, making them ideal for outdoor use. Furthermore, low water uptake of the composites helps providing a dimensionally stable product in the presence of moisture or when under water. These attributes combine to make 2mm HDPE Sheet ideal for a variety of industrials and consumer applications due to its unique characteristics, including moisture, chemical, and impact resistance.

Thickness Variations and Their Applications in Practice

HDPE plastic sheets come in a variety of thicknesses for various applications. Thinner sheet is used in packaging, insulation and recordable media, thick sheet is used for the building materials industry (cladding) and in the manufacture of vehicles. The 2mm HDPE board is often considered in commercial and industrial markets as it is easy to manipulate, and inflicts lower cost. It is often utilized in wall paneling, tank lining and machined parts. In addition, thickness choice influences the flexibility, load-bearing capacity and service life of the sheet as well as the appropriate requirements for a specific application concerning strength. The correct thickness is to optimize the performance, and not overbearing or breaking your bank.

Nuts And Bolts Of 300 Micron HDPE Sheets

300 micron HDPE sheers are commonly used in Agriculture, Construction and Packaging. Due to their lightweight design, it is easy and convenient to move and put in place. at the same time, It can perfectly protect against 2mm or so dust. With 300micon HDPE, users get same level of matte effect They can predict how much material to plan for and have a very clear idea of what an object will cost. This thickness is most commonly used for temporary coverings, ground protection and as a barrier. Their demand has, in fact, been increasing because of their low cost and high performance. Knowing the physical properties of 300 micron sheets allows buyers to choose accordingly in terms of durability needs and size of project.

Pricing Factors and Market Considerations

The price of 300 micron HDPE sheet varies according to a number of factors, such as raw material cost, production scale, production technology and size. The price will also have an impact based on market demand, customisation requirements and additives such as UV stabilisers. Volume discount pricing also allows for lower material costs and this makes HDPE sheets a low cost solution extracted from large projects. Cost despite fluctuations in the cost of 300 Micron HDPE Sheet Price, are still economical because they last so long and require very little maintenance. Too much focus on price, less on consistent quality and accuracy of scraping thickness, material yield and the supplier’s reliability.

Industrial, Agricultural, and Commercial Applications

HDPE sheets The versatility of HDPE has made it very popular across a wide range of industrial, agriculturafil and commercial applications. In agriculture, they are used as pond liners and mulch films and to protect foliage. Manufacturing uses are chemical tank linings, conveyor parts and protective barriers. In commerce, HDPE sheets are used for cuttings boards, food preparation, water pipe flanges (HDPE pipe grade), outdoor and indoor playground systems, marine construction (pile guards, bumpers, anti-skid surfaces) and livestock stalls. They have the added bonus of being bacteria resistant and clean easily too, making them viable for food environments. From a 2mm HDPE sheet for added structural support to a thinner version for surface protection, the product remains consistently reliable in multiple applications.

Sustainability, Safety, and Long-Term Benefits

Also, HDPE sheets are more environment friendly as they can be recycled. 100% of their packaging material is recyclable – reducing environmental impact further through recycling and when reused or repurposed. HDPE does not post harmful chemicals, so it is acceptable for use in natural gas transfer lines and oil return lines. With a long service life, not easy to damage and no excessive wiry material wasted. Furthermore, there is no maintenance required for HDPE sheets which also saves labor costs and operational time. Most of these reasons go hand in hand with contemporary sustainability motives, so HDPE is a responsible option for any business that prides itself on efficiency and being eco-friendly.

Conclusion: An intelligent material with more to offer - HDPE Sheets

HDPE sheet provides the very highest protection for goods in transit and is perfect for returnable transit packaging or storage applications. With knowledge of things like 2mm HDPE sheet, you clearly want to be having a good think about the 300 Micron HDPE Sheet Weight Per Sqm and the weight per sqm for example when it comes to going a step further in your decision making. Their wide usage, resistance to extreme conditions and recyclability makes them a future material. With continuous evolution of industries, HDPE plastic sheets are still a popular among many consumers who need them for their application that requires both safety and performance.

Frequently Asked Questions (FAQs)

What is the use of a HDPE sheet?

High-Density Polyethylene (HDPE, Type I) sheets provide excellent resistance to chemicals and moisture, and are easy to clean; making them ideal for tanks in a variety of industrial applications where very low temperatures or very high chemical levels require an extra level of durability.

What is the benefit of using a 2mm HDPE panel.

A versatile and durable product, 2mm HDPE sheet is suitable for wall cladding, partitions and work surfaces and can be easily fabricated for use in other applications where good performance at a value price is required.

What is the weight per sqm of 300 micron HDPE?

PRICE The price is per m² e 300 micron HDPE sheet kg/m² thickness x material weight,It allows to evaluate handling, transport requirement and product quantity precisely.

What are the factors affecting the price of 300 micron hdpe sheetfi?

Raw material, size, additives, quality, order quantity and market demand are the main impact factor to shape the price of 300 micron HDPE sheet.

Who is the largest supplier of HDPE Sheet?

We are one of the reckoned manufacturers and suppliers of HDPE Sheet by Singhal Industries Private Limited Known for features such as reliable performance, precise dimensions and longer service life, these sheets are highly regarded in the industry; Typical standard thickness is ½” (11ga); however other gauges may be available upon request.